This information is taken from the book The Prussian Cavalry of the Napoleonic Wars 1792-1807 by Peter Hofschroer

Hussar Headwear

Headwear was either the Colpack or the

Mirliton. Shakos were introduced in 1804, and in the 1806 ‘campaign’ a mixture

of headwear was apparent. The hats worn by Regiments No. 1 and 4 were 11 inches

high and Regiments No. 2,3,9 and 12 were 12 inches high. A plume was fixed on

the right side of the hat. For troopers it was white, NCO’s had a black tip,

and Carabineers wore white with three black rings. The officer’s plume was made

of heron’s feathers and had a black base. The cords ran around the hat and two

tassels hung on the right hand side. The officer’s hat cords were gold or

silver, depending on the colour of the frogging on their uniforms. In 1796 Colpacks were abolished and replaced by

Mirlitons with a small folding weather flap or peak on the front. Cords and

plumes were similar to those worn on the Colpack. Although the shakos of the

Russian style were introduced o 1804, most regiments went to war in 1806 in

their old Mirlitons. The colour of the shako cords was used to distinguish the

squadron within a regiment.

Hair was long and plaited, weighted with

pistol balls. Moustaches were permitted and were grown by almost every Hussar.

1. NCO; Hussar Bn. No.11, 1792-1804

2. Carabineer, Hussar Regt No.1, 1794

3. NCO; Hussar Regt No.1, 1794

1. Officer, Hussar Regt No.5, 1806

2. Officer, Hussar Regt No.7, 1806

3. Trumpeter, Hussar Regt No.2, 1806-07

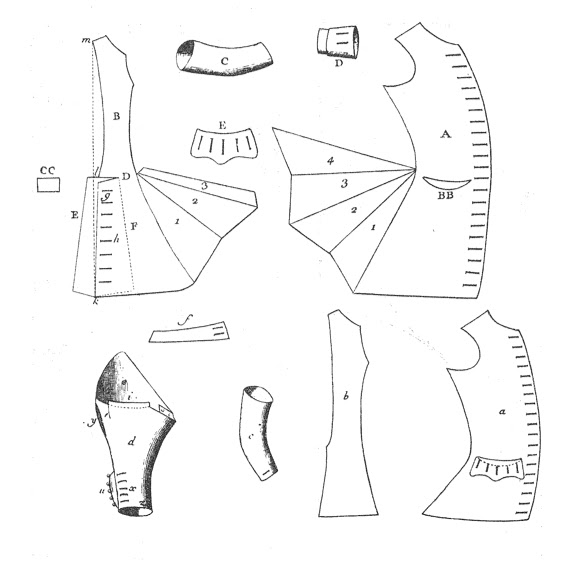

Hussar Dolman

A Hussar Dolman was a highly decorated

garment. The collars and cuffs were coloured in some regiments, and in others

they were the same colour as the body and marked only by trim. This trim also

ran down the front of the dolman and around the tails. The pocket and back

seams were also trimmed, the designer of the trim varied from regiment to

regiment; officers had gold or silver trim. There were between ten and eighteen

lines of frogging with three to five rows of buttons, brass or tin according to

the colour of the frogging. From 1800 the cut of the dolman as altered

slightly, the collars becoming higher and the tails shorter.

1. Sgt. Major, Hussar Reg No.8, 1806

2. Trooper, Hussar Regt No.7, 1806

3. Trooper, Life Hussar Regt. Rudorff (No.2), 1806

Pelisse

The Pelisse is a fur-lined jacket, which is

similar in cut to the dolman. The fur at the collar or cuff was normally black

or white. It was worn over the left shoulder on parade, attached by a cord.

Depending on the time of year, either the dolman or the pelisse was worn.

Barrel-sash consisted of a bundle of cords

fixed together and wrapped around the waist several times. It was worn only

over the dolman. Officer’s sashes were made of silver cord ‘shot with black’.

Trousers were made of white kid leather.

Overalls had piping in the colour of the

frogging, and were worn over the trousers. Cloth trousers were worn in winter.

Buttoned up overalls were also worn, and the colour of the piping was used to

distinguish the squadrons within a regiment.